Welcome.

This is where you start. Unfortunately, the new posts are at the top, with each earlier post falling down the page. So start at the bottom, read, go up the page one, read, go up the page one, and so on. Got it? Didn't think so..

I appreciate the many people I have learned from, on a number of topics, who have provided detailed information on projects they have undertaken. So I have decided to document the construction of a CNC router I am building.

I know nothing about blogging so bear with me as I jump in with both feet.

Before we begin, in case you are not aware of this fact:

CNC operations can be VERY DANGEROUS.

You are dealing with high speed power tools, potentially lethal electricity, powerful motors and parts that can move without warning, parts that can spin so rapidly and violently that they can come apart at the speed of a bullet, all controlled by computer, which may activate components without notice. Other considerations are extreme sound levels, extreme dust levels and a number of things can be very heavy.

You need to carefully be aware of every aspect of what you are creating and take proper care to protect yourself and OTHERS who will be around your operation. Safety glasses, breathing protection and hearing protection must be worn by everyone, and it is YOUR responsibility to keep the operation of your equipment safe. You must provide safety guidance for your family, pets and friends who will not be aware of the potential dangers of your CNC operation. With this warning, by continueing past this point, you agree to hold me blameless.

If you are in any doubt, be sure to seek guidance from a professionally qualified expert, rather than risk injury to yourself or to others.

An excellent resource for all things CNC is: The CNC Zone forums

A while back (May 2006), I became aware of the benefits of being able to create parts using the process of CNC (Computer Numerical Control). It allows you to use CAD (Computer Aided Drafting) to create models of physical objects which can then be output to a machine which has the capability of recreating that design in the real world. This machine will use X/Y/Z axis and possibly later a fourth axis. The basis for the machine is the chopper driver board. It takes information from the software and converts it into electrical signals that drive the motors very accurately.

To that end, I decided to build a CNC Foam Cutter, which was based off of the 8linx design. Because of other projects, this project got pushed to the back burner. I had purchased a 4-axis chopper stepper driver board kit with (4) 200oz-in stepper motors from HobbyCNC. I assembled the kit a few months after receiving it, but because of the necessity for focus, I put off installing the driver chips (very static sensitive) and their testing for about a year. Finally, in the fall of 2009, I soldered the driver chips into the board, set the Vref voltages, and connected the motors. I held my breath and flipped the switch, and the motors all 'locked' up, as they should. I set the project aside until this spring, when I attached a computer and the parallel cable and attempted to control the motors from the Mach3 software. I have learned alot since then; I have now been able to set up several computers including two laptops to be able to send signals from Mach3. One of my laptops is actually running a pcmcia card parallel port successfully (probably my best system).

To that end, I decided to build a CNC Foam Cutter, which was based off of the 8linx design. Because of other projects, this project got pushed to the back burner. I had purchased a 4-axis chopper stepper driver board kit with (4) 200oz-in stepper motors from HobbyCNC. I assembled the kit a few months after receiving it, but because of the necessity for focus, I put off installing the driver chips (very static sensitive) and their testing for about a year. Finally, in the fall of 2009, I soldered the driver chips into the board, set the Vref voltages, and connected the motors. I held my breath and flipped the switch, and the motors all 'locked' up, as they should. I set the project aside until this spring, when I attached a computer and the parallel cable and attempted to control the motors from the Mach3 software. I have learned alot since then; I have now been able to set up several computers including two laptops to be able to send signals from Mach3. One of my laptops is actually running a pcmcia card parallel port successfully (probably my best system).

This is where you start. Unfortunately, the new posts are at the top, with each earlier post falling down the page. So start at the bottom, read, go up the page one, read, go up the page one, and so on. Got it? Didn't think so..

I appreciate the many people I have learned from, on a number of topics, who have provided detailed information on projects they have undertaken. So I have decided to document the construction of a CNC router I am building.

I know nothing about blogging so bear with me as I jump in with both feet.

Before we begin, in case you are not aware of this fact:

CNC operations can be VERY DANGEROUS.

You are dealing with high speed power tools, potentially lethal electricity, powerful motors and parts that can move without warning, parts that can spin so rapidly and violently that they can come apart at the speed of a bullet, all controlled by computer, which may activate components without notice. Other considerations are extreme sound levels, extreme dust levels and a number of things can be very heavy.

You need to carefully be aware of every aspect of what you are creating and take proper care to protect yourself and OTHERS who will be around your operation. Safety glasses, breathing protection and hearing protection must be worn by everyone, and it is YOUR responsibility to keep the operation of your equipment safe. You must provide safety guidance for your family, pets and friends who will not be aware of the potential dangers of your CNC operation. With this warning, by continueing past this point, you agree to hold me blameless.

If you are in any doubt, be sure to seek guidance from a professionally qualified expert, rather than risk injury to yourself or to others.

An excellent resource for all things CNC is: The CNC Zone forums

A while back (May 2006), I became aware of the benefits of being able to create parts using the process of CNC (Computer Numerical Control). It allows you to use CAD (Computer Aided Drafting) to create models of physical objects which can then be output to a machine which has the capability of recreating that design in the real world. This machine will use X/Y/Z axis and possibly later a fourth axis. The basis for the machine is the chopper driver board. It takes information from the software and converts it into electrical signals that drive the motors very accurately.

To that end, I decided to build a CNC Foam Cutter, which was based off of the 8linx design. Because of other projects, this project got pushed to the back burner. I had purchased a 4-axis chopper stepper driver board kit with (4) 200oz-in stepper motors from HobbyCNC. I assembled the kit a few months after receiving it, but because of the necessity for focus, I put off installing the driver chips (very static sensitive) and their testing for about a year. Finally, in the fall of 2009, I soldered the driver chips into the board, set the Vref voltages, and connected the motors. I held my breath and flipped the switch, and the motors all 'locked' up, as they should. I set the project aside until this spring, when I attached a computer and the parallel cable and attempted to control the motors from the Mach3 software. I have learned alot since then; I have now been able to set up several computers including two laptops to be able to send signals from Mach3. One of my laptops is actually running a pcmcia card parallel port successfully (probably my best system).

To that end, I decided to build a CNC Foam Cutter, which was based off of the 8linx design. Because of other projects, this project got pushed to the back burner. I had purchased a 4-axis chopper stepper driver board kit with (4) 200oz-in stepper motors from HobbyCNC. I assembled the kit a few months after receiving it, but because of the necessity for focus, I put off installing the driver chips (very static sensitive) and their testing for about a year. Finally, in the fall of 2009, I soldered the driver chips into the board, set the Vref voltages, and connected the motors. I held my breath and flipped the switch, and the motors all 'locked' up, as they should. I set the project aside until this spring, when I attached a computer and the parallel cable and attempted to control the motors from the Mach3 software. I have learned alot since then; I have now been able to set up several computers including two laptops to be able to send signals from Mach3. One of my laptops is actually running a pcmcia card parallel port successfully (probably my best system).March of 2010 brought me to WoodworkerB's Blog where he describes his CNC router build. I decided that was a much better use of my driver and the simplicity of his design was far better than the BuildyourCNC design. In fact, I feel like with my engineering background, I will be able to improve a bit on WoodworkerB's design in useability, efficiency, and accuracy; but his fundamental project is quite stellar in it's foundation of design and simplicity of construction and inexpensiveness of aquisition. One of the downfalls of the dimensions of the basic design is the lack of full utilization of the table area.

Also, I discovered McMaster-Carr sells acme threaded drive rod stock in either 36" or 72" base sizes. So I am modifying my design to utilize these sizes. I have purchased my aluminum angle from OnlineMetals.com. I bought (5) sticks of 0.125"x0.75" 6063-T52 Extruded Architectural Aluminum Angle at $4.39 each plus $4.50 'cutting fee'+$15 shipping.

I also purchased a sheet of MDF at Lowes for ~$32.00. MDF comes in sheets of 49"x97", which is nice because it allows some 'burn' for saw kerfs, or whatever (std plywood is 48"x96"). It is also heavier than H-E-Double Hockey Sticks.

And 24 sk8zz8 Skateboard Bearings 608Z Shielded from VXB.com for about $17 w/ shipping. I still have a few parts to get. Soon I will post some 3-D drawings I am creating in SolidWorks 2007.

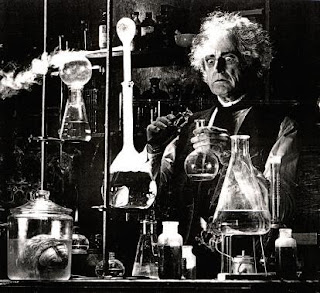

And what does this crazy guy look like, you ask?

Glad you asked:

Also, I discovered McMaster-Carr sells acme threaded drive rod stock in either 36" or 72" base sizes. So I am modifying my design to utilize these sizes. I have purchased my aluminum angle from OnlineMetals.com. I bought (5) sticks of 0.125"x0.75" 6063-T52 Extruded Architectural Aluminum Angle at $4.39 each plus $4.50 'cutting fee'+$15 shipping.

I also purchased a sheet of MDF at Lowes for ~$32.00. MDF comes in sheets of 49"x97", which is nice because it allows some 'burn' for saw kerfs, or whatever (std plywood is 48"x96"). It is also heavier than H-E-Double Hockey Sticks.

And 24 sk8zz8 Skateboard Bearings 608Z Shielded from VXB.com for about $17 w/ shipping. I still have a few parts to get. Soon I will post some 3-D drawings I am creating in SolidWorks 2007.

And what does this crazy guy look like, you ask?

Glad you asked: